This machine mixes resin with fiber and chops it up to prep it for the compression molder

Natural composite consisting of banana fiber with partially recycled plastic

In the other lectures throughout the day a variety of other aspects about the recycling of composites were discussed including the importance of labeling and separating for ease of recycling, the challenges of chopping up old fighter jets into chopped carbon fiber, and the future of recycling asphalt roofing shingles. The strength of using chopped fiber versus virgin continuous strand was also discussed. Some vendors had begun to set out their product samples, such as Polystrand’s line of recycled corrugated thermoplastic plastic panels utilizing continuous fiber reinforcement.

After the lectures, there was a tour of UAB’s composites research lab. The facilities are used by the composite engineering graduate students both for original research as well as for R&D and manufacturing for private companies. Equipment included machines for testing as well as for manufacturing. Demonstrations for us included a machine that was used to create custom pellets where composite materials could be combined with resins in custom combinations. Most interesting to me was the combination of partially recycled thermoplastics that were combined with natural fiber such as banana fiber to create green composites. The fact that these could be formed on site was very exciting. They also demoed their compression molding machine with this green composite formulation.

- a green composite sample consisting of banana fiber and partially recycled plastic

For part 1 of this series, please click here.

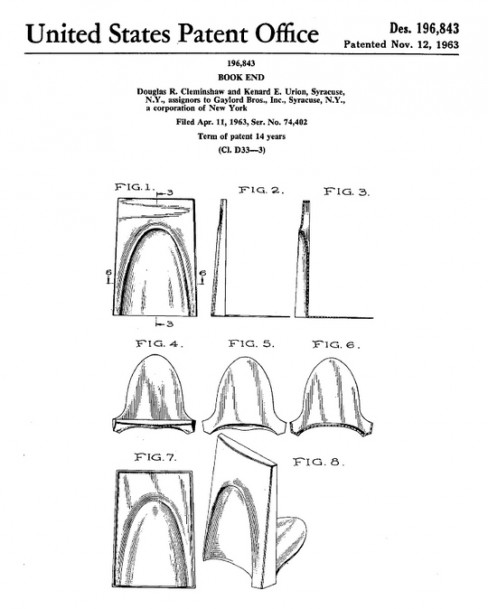

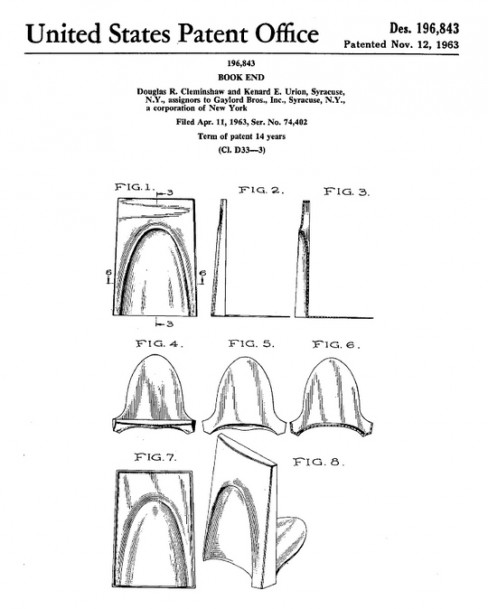

Might these be the world’s first plastic book ends?

For those reading this that did not go to school for industrial design, we have a class called “materials and processes” where we are taught how things are manufactured and what they should be made out of. I remember many things taught to me by my “materials and processes” professor at RIT, Doug Cleminshaw. The man knows plastic. He wrote a book about it for one thing. Most impressive to me was the rumor that he designed the world first plastic book ends.

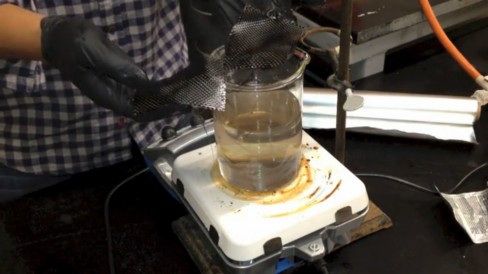

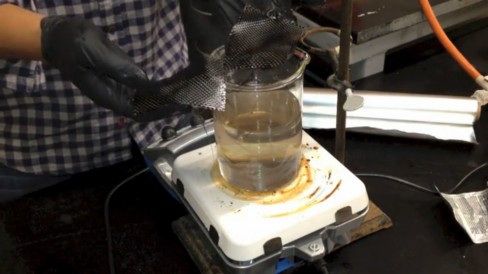

The biobased epoxy has been removed

So one of the things that we learned about plastics was that there are two main types of plastics, Thermosets and Thermoplastics. Thermoplastics are formed using heat and include plastics such as polypropylene (one of my personal faves), acrylic, and styrene. Thermosets are formed as a result of a chemical reaction and include epoxies, melamine, and Bakelite. This chemical reaction has traditionally been thought of as not being reversible. It was for this reason that Doug explained to our class that Thermosets were not recycled, while thermoplastics could be recycled a number of times until they degrade.

Chemical researcher Stefan J. Pastine, Ph.D. of Connora Technologies is working to change that fact. I saw him speak back in June at UAB’s Composite Conference here in Birmingham, AL. He has developed “the world’s first recyclable epoxy plastic”, called Recyclamine. Through an environmentally benign process that takes place at 100 degrees, Recyclamine can be recovered so as to be later reused. This absolutely blew my mind. This means that an old carbon fiber bike frame could theoretically one day be chopped up and completely reused. Not just the carbon fiber, but the expoxy “glue” that holds the carbon fiber together. Incredible. Carbon fiber and other high tech composites have always been great for the environment in their combination of lightness and strength which leads to impressive energy savings, but the fact that they could not be recycled was a major drawback. Dr. Pastine is currently working to make the process cost effective enough to be competitive with current resins used in composites, so keep an eye out.